The Important Role of Line Gas Regulators

Line gas regulators play a pivotal role in the efficient and safe delivery of gas, be it in residential, commercial, or industrial settings.

At their core, line gas regulators act as guardians, ensuring that gas from the supply source is consistently delivered at the right nominal inlet pressure range of the appliance or equipment it supplies. This consistency is crucial, as many appliances and processes require a stable gas pressure to operate efficiently and safely. Imagine lighting a gas stove and experiencing erratic flames due to fluctuating gas pressure; not only is it inefficient, but it also represents a safety hazard.

Furthermore, line gas regulators are instrumental in preventing dangerous pressure spikes. A sudden surge in gas pressure can result in damage to appliances, cause ruptures in the gas lines, or even lead to catastrophic explosions. By actively monitoring and adjusting the pressure, these regulators act as the first line of defense against such potential dangers.

Essentially, a line gas regulator is to the gas system what a thermostat is to a heating system: a control mechanism that ensures optimal and safe operation.

Quick Links

- 9 Key Features of Line Gas Regulators

- Common Applications of Line Gas Regulators

- Is there a difference between a line regulator and an appliance regulator?

- When do you need a line regulator?

- How to select a service regulator?

9 Key Features of Line Gas Regulators

Here’s an overview of the main features of a line gas regulator:

- Pressure Control Mechanism: The pressure control mechanism is the primary feature of any gas regulator. It allows the regulator to maintain a constant output pressure even when there are fluctuations in the input pressure.

- Diaphragm: The diaphragm is a flexible membrane that responds to changes in the outlet pressure. As the pressure changes, the diaphragm moves, causing the regulator to adjust and maintain the set pressure.

- Loading Mechanism: The loading mechanism sets the desired output pressure. This can be done via a spring (spring-loaded), weight (weight-loaded), or even electronically in some advanced regulators.

- Valve & Orifice: The valve and orifice are the primary control elements. They adjust the flow of gas in response to the diaphragm’s movement, allowing more or less gas through based on the current pressure.

- Vent: The vent is a safety feature that allows the regulator to release excess pressure. This ensures that if there’s an over-pressure situation, the gas has a safe way to escape, preventing potential hazards.

- Overpressure Protection: Some line regulators come with built-in safety mechanisms that automatically shut off the gas flow if the pressure exceeds a certain limit.

- Underpressure Protection: Similar to the overpressure feature, this shuts off the flow if the pressure drops too low, ensuring appliances receive gas at safe pressures.

- Filter or Strainer: Some regulators come equipped with a filter or strainer that prevents debris from entering and damaging the regulator or downstream equipment.

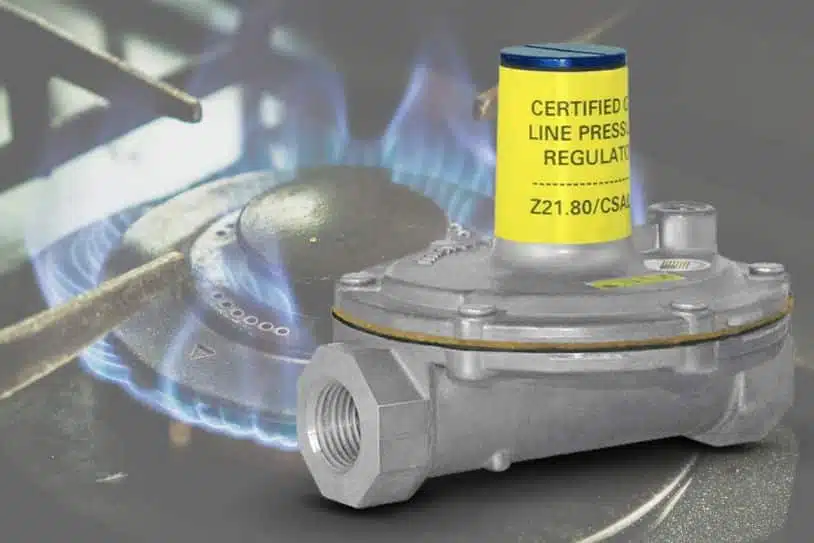

- Compliance with ANSI Z21.80/CSA 6.22: Line regulators comply with ANSI Z21.80/CSA 6.22, which differentiates them from appliance regulators which comply with ANSI Z21.18/CSA 6.3.

Common Applications of Line Gas Regulators

Line gas regulators are omnipresent, playing a critical role in a multitude of settings, ensuring that gas pressures are maintained at safe and efficient levels. Here’s a closer look at where they’re commonly employed:

- HVAC Systems: In heating, ventilation, and air conditioning (HVAC) applications, line gas regulators ensure that fuel, whether it’s natural gas or propane, is delivered at the right pressure. This ensures efficient combustion, optimal performance, and longevity of the HVAC equipment.

- Combustion Equipment: Devices that rely on combustion, such as boilers and furnaces, require a consistent gas supply at a specific pressure. Regulators ensure this consistency, preventing possible hazards and inefficiencies due to fluctuating gas pressures.

- Propane Appliances: Propane-powered appliances, from backyard grills to industrial ovens, rely on line gas regulators to safely reduce the gas line or tank pressure to a usable level for the appliance.

- Utilities: For utility companies, line gas regulators are used in distribution systems to reduce the high pressure of transported gas down to a level that’s safe and usable for residential and commercial consumers.

Is there a difference between a line gas regulator and an appliance regulator?

Yes, there is. The main difference between a line regulator and an appliance regulator lies in their specific applications and standards. A line regulator, such as Maxitrol’s 325-L series, is designed to reduce the gas pressure in the main supply line to a level suitable for gas appliance operation. These regulators comply with ANSI Z21.80/CSA 6.22 standards and are often used in larger systems where gas is distributed at higher pressures (up to 5 PSI), requiring reduction before reaching individual appliances.

In contrast, an appliance regulator, like the Maxitrol RV Poppet Series, directly controls gas pressure at the point of use – the appliance itself. They are certified to ANSI Z21.18/CSA 6.3 standards and are designed for low-pressure applications, ensuring that the gas pressure supplied to the appliance is within its safe operating range. Another thing to note is that appliance regulators are mainly found in the manufacturer’s appliances or equipment, unlike line regulators which are installed directly on the gas line.

In short, line regulators manage overall system pressure, while appliance regulators adjust the pressure to the specific needs of each device.

When do you need a line regulator?

You need a line regulator in situations where the pressure of the gas in the main supply line is higher than what your gas appliances can safely handle. This is typically the case in systems where natural gas is distributed at pressures higher than what standard appliances are designed to operate at. For instance, if the gas in the supply lines is distributed at 2 PSI, but your appliances require a lower pressure (like 7 to 11 inches of water column (WC), as is common), a line regulator is necessary to reduce this higher pressure to a safe and manageable level for the appliances.

Line regulators are particularly essential in larger installations or commercial settings where the gas supply needs to be distributed over long distances or to multiple appliances. In these cases, higher pressure in the main lines helps maintain efficient gas flow. The line regulator then steps in to ensure that the pressure is adequately reduced before it reaches each appliance. Without a line regulator in such setups, the excessive pressure could damage appliances, lead to safety hazards, or result in inefficient operation of the gas appliances.

How to select a service regulator?

Selecting a line regulator for a gas system requires careful consideration of several factors to ensure the regulator meets the application’s specific needs. Here are the things to consider when selecting the right line regulator:

- Type of Gas: Determine the type of gas used (e.g., natural gas, propane). Different gases may require different types of regulators.

- Inlet Pressure: Identify the maximum inlet pressure that the regulator will need to handle. This is the pressure in the main supply line before it is reduced.

- Outlet Pressure Requirements: Establish the desired outlet pressure, which is the reduced pressure after passing through the regulator. This should match the operational requirements of the appliances or systems downstream.

- Flow Rate: Calculate the total flow rate required by all appliances or systems that the regulator will supply. The flow rate is typically measured in BTU/hr and is crucial for selecting the right size regulator.

- Sizing: Choose a regulator size that can handle the required flow rate without overloading. An undersized regulator can lead to an inadequate gas supply, while an oversized one can be inefficient.

- Environmental Factors: If the regulator will be installed outside, consider factors like temperature ranges, weather exposure, and potential for corrosion. Select a regulator that is built to withstand these conditions.

- Compliance with Standards: Choose a regulator that complies with current safety standards and certifications, such as those from ANSI or CSA.

- Overpressure Protection: For certain applications, especially where inlet pressure can greatly exceed outlet pressure requirements, consider a regulator with overpressure protection features.

- Manufacturer Reputation and Warranty: Opt for a regulator from a reputable manufacturer with good customer support and warranty provisions.

- Material Quality and Durability: Choose a regulator made from materials suitable for your application, especially considering factors like corrosion resistance.

- Safety Features: Depending on your specific needs, you may require additional features like internal relief valves, integrated shut-off mechanisms, or vent-limiting devices for indoor installations.

In Conclusion

The role of line and service gas regulators is to ensure the safe and efficient delivery of gas to various appliances and equipment. These regulators serve as critical control mechanisms, maintaining consistent inlet pressure and guarding against dangerous pressure spikes. They are essential in applications such as HVAC systems, combustion equipment and utility services. When selecting a line regulator, make sure you understand all the requirements of your applications and select the line regulator accordingly. This careful selection will ensure the safe and efficient operation of your gas supply system, whether residential or commercial.

The experts at Norgas understand the requirements of various gas supply systems and can help you choose the right line regulators that take into account all the requirements and conditions of your application and gas supply system. In addition to line and service regulators, we offer a comprehensive selection of gas regulators such as back pressure regulators and high pressure regulators. Contact us for more information on how we can help you.