How Does a Diaphragm Gas Meter Work?

Natural gas consumption has increased considerably in the past few years, especially in Canada. According to the latest data by Worldometer, Canada is the 6th largest consumer of natural gas worldwide.

Naturally, gas companies need measuring devices when supplying gas to clients. That’s to ensure customers only get a bill for what they’ve used.

A gas meter is a measuring device that records the volume of gas supplied to a customer’s premises. Although there are different gas meters, such as rotary, turbine, and Coriolis meters, we are here to discuss how the diaphragm gas meter works.

What are Diaphragm Gas Meters?

The diaphragm gas meter is one of the oldest and most commonly used types of gas meter ever since its development in the 19th century. The meter has four chambers separated by two walls known as diaphragms. It also has rotating pistons that link the diaphragms.

Diaphragm gas flow meters are positive displacement meters or volumetric flow meters. As the name suggests, they work by measuring the exact volume of gas as it passes through the chamber compartments.

How Does a Diaphragm Gas Meter Work?

Diaphragm meters work using the same principle as rotary meters, consisting of chambers separated by a diaphragm and deformable wall. These chambers fill up and expel gases alternately.

The process starts when the gas enters through the inlet in one chamber. When it fills, the pressure forces the diaphragm to squeeze the gas out through the outlet via the valves. That action pushes the gas into the other chamber.

When the other chamber is full of gas, it pushes it out of the outlet. During each cycle, as one part of the chamber is full, the other is empty. Every cycle rotates the measuring piston.

You measure the gas used by multiplying the diaphragm plates’ travel distance by their surface area. When taking readings of a diaphragm plate meter, you read and record the numbers starting from the left side.

Diaphragm meters can work with gases up to a pressure of 0.5 bar, allowing flows over 160m3/hr, and low temperatures of up to -4° F and highs of 122° F.

In some cases, you might need to install a pulse generator in the gas meters. The pulse generators are attached to the odometer, and their function will be to collect the pulse counts and record them on a pulse data logger.

The counts are converted into readable data and transmitted to an AMR (automated reading system). AMR is a technology that automatically collects data from electric and gas meters. This data is helpful in billing and detecting unusual usage and possible tampering of the meter.

Applications of Gas Diaphragm Meters

Diaphragm gas meters are reliable and give accurate results, making them suitable for a wide range of applications. That said, these are some of the more common applications of diaphragm gas flow meters:

- Residential homes: Used to determine the amount of natural gas a household consumes.

- Hospitals: Useful when metering gas supply to hospital devices such as anesthetic machines.

- Custody transfer: Refers to transferring natural gas or oil products from one operator to another. The high accuracy of the diaphragm meters makes them suitable for custody transfer of natural gas.

- Commercial use: These are capable in light commercial applications, measuring gas amounts with low pressure and low flow rate. Unlike turbine flow meters, they are unsuitable for high-pressure gases in large industrial applications.

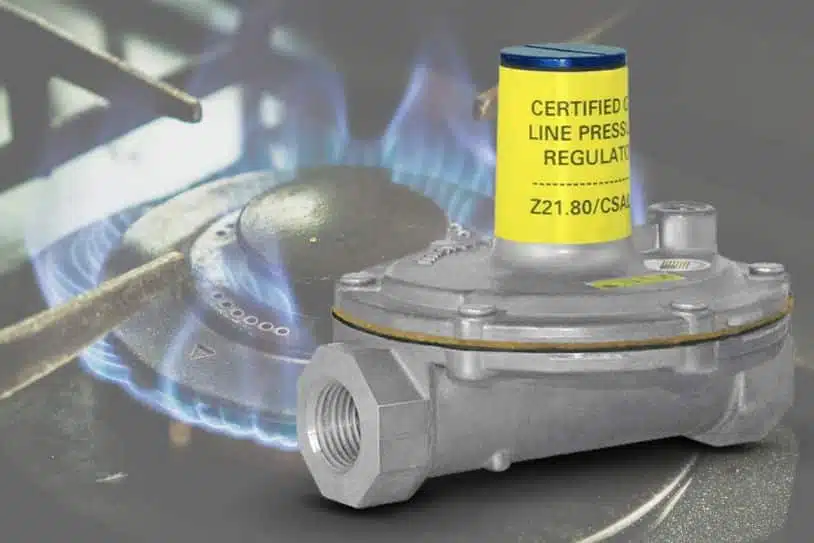

Image source: ^ Missi ^ on Flickr

Pros and Cons Diaphragm Gas Meters

Pros

- Relatively affordable.

- High accuracy

- Robust so long-lasting.

- Easier to handle and install.

- Compact and lightweight.

- Have temperature and pressure compensation mechanisms.

Cons

- Require regular servicing.

- Gas can leak from gaps around the diaphragm and the valves.

- Not suitable for high pressured gases with a high flow rate.

Final Word

Diaphragm meters are positive displacement natural gas flow meters, just like rotary gas meters. They are primarily used in residential and small commercial installations as a reliable and low-cost means of measuring a minimal gas flow for billing purposes. It’s important to understand how a diaphragm meter works to make sure it’s right for your application.

Contact our team of experts today for more information on gas meters. We’ll be happy to recommend the best gas meters, gas regulators, and gas valves for your application. Plus, we have a large inventory of products ready to ship, no matter how large or small your order.