Positive Displacement Gas Meters: Rotary and Diaphragm

Positive displacement gas meters, also called PD gas meters, are among the most-used meters for utility billing applications as well as custody transfer of natural gas. Based on traditional gas technology, PD gas meters operate without any power supply, do not require straight downstream or upstream pipes for installation, and provide highly precise results and high turndown. This makes them a robust option for measuring gas volumes, even in the face of newer, technologically advanced gas meters.

Read on to learn the basics of positive displacement gas meters, including their mechanism, types, applications, and pros and cons.

Composition of Positive Displacement Gas Meters

Positive displacement gas meters are flow meters that measure the volumetric flow rate of a moving gas by dividing it into fixed metered volumes. Essentially, they measure the volume of the gas passing through the flow meter by repeatedly entrapping the gas in order to measure its flow.

Structurally, the PD meters feature a fixed-volume chamber that impedes the gas flow and a rotating or reciprocating mechanism that allows the known-volume gas to pass through the chamber. The number of rotations determines the total gas volume, while the reciprocation rate helps in calculating the flow rate. Think of it as filling up a bucket with fluid and dumping the contents downstream. The number of times that you fill and empty the bucket usually indicates the flow of gas through the flow meter.

Positive displacement gas meters come in a range of sizes – from 1/4″ to 12″ and can operate with turndowns as high as 100:1, although the typical range is 15:1 or lower. Since PD gas meters feature reduced slippage between the flow meter components, your application gets better metering accuracy.

Main Types of PD Gas Meters

There are two types of positive displacement gas meters mainly used in the gas industry: Diaphragm gas meters and rotary gas meters. Both are considered traditional technology and are still widely used in custody transfer of natural gas and utility billing applications.

Diaphragm Gas Meters

Applications:

Because they have a high turndown rate, diaphragm meters are ideal for low to medium capacity residential and commercial applications and for pilot gas metering. Class 250 (250 CFH) diaphragm gas meters are typically installed by gas utilities on homes. Class 400 to 1000 (400 CFH to 1000 CFH) commercial and light industrial sizes are available for higher capacities.

Learn more about diaphragm gas meters.

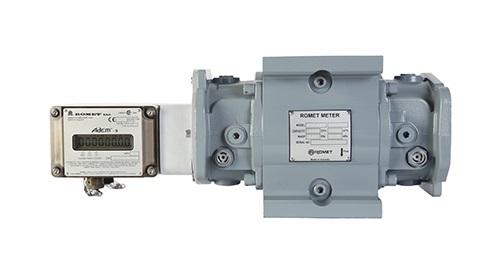

Rotary Gas Meters

Rotary gas meters feature spring-loaded vanes that divide the spaces between the vanes into discrete volumes and move the gas from inlet to outlet and discharge. The number of vane rotations helps in determining the flow rate.

Rotary gas meters such as Romet rotary gas meters are pressure tested up to 4x the maximum allowable operating pressure (MAOP) and certified for measurement accuracy in accordance with the requirements of ANSI B109.3. These gas meters are equipped with mechanisms to always maintain accuracy and reliable measurement.

Applications:

Rotary gas meters are typically installed on large-scale commercial and industrial applications. They offer excellent turndown and capacities from 600 CFH to 56,000 CFH. They can be combined with electronic modules for improved accuracy.

Learn more about rotary gas meters.

Advantages of Positive Displacement Gas Meters

There are many benefits of using positive displacement gas meters for measurement or monitoring applications. PD gas meters offer:

- An affordable measuring solution specifically for gas utility billing

- A choice of capacities to suit many residential, commercial and industrial applications

- Extremely high levels of accuracy in the measurement of flow rate due to minimal by-pass or slippage.

- The ability to process a wide range of viscosities while remaining accurate over several cycles and ensuring high repeatability.

- Error-free performance for years, which ensures strong reliability and precision at very low operational and maintenance costs.

If they are the right fit for the application, most PD gas meters may not need servicing and recalibration for as long as 10 to 20 years of continuous use. However, PD gas meters could pose accuracy challenges with dirty gas as it creates a drop in pressure.

Find the Right PD Gas Meters

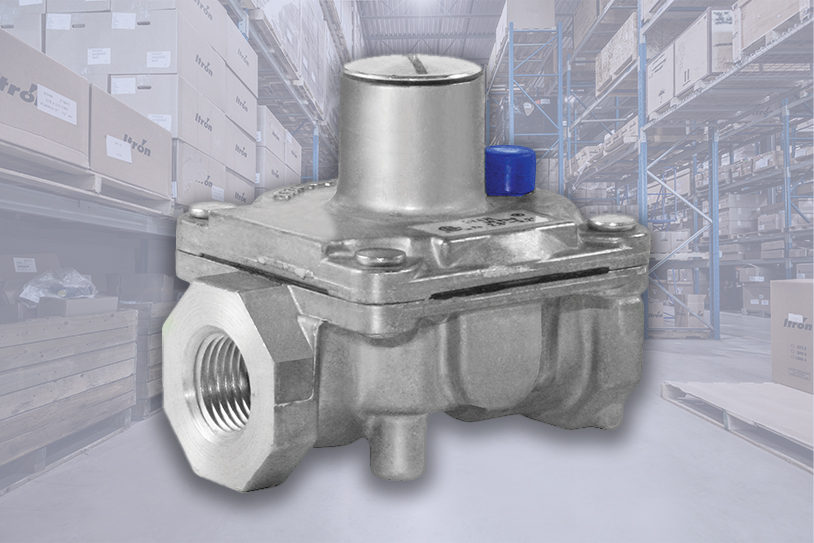

Positive displacement gas meters work best with clean, non-erosive, non-corrosive gases, and most models do not tolerate impurities. Hence, while choosing PD gas meters, it is important to partner with a team of specialists that can help you find the right fit for your specific applications.

At Norgas Controls, we have years of experience and expertise in providing tailor-made gas regulation and gas measurement solutions to a diverse set of clients. You can count on us for excellent stock availability, quick processing and shipping, competitive pricing, and dependable technical support for a wide range of gas meters, gas valves, and gas regulators.

For more information on our positive displacement gas meters selection, call us at 514-697-8439 or 888-GAS-REGS (427-7347). You can also contact us online.