Everything You Need to Know About Rotary Gas Meters

In 2020, approximately 3.9 trillion cubic feet of natural gas was consumed in Canada. In order to monitor and bill gas consumption, natural gas supply companies use different types of metering devices. Among the most popular and traditional ones, you’ll find the rotary gas meters.

Affordable and accurate, rotary gas meters, like diaphragm gas meters, are classified as positive displacement gas meters. Read on to learn all about rotary gas meters, from how they work to how they are installed.

What Is a Rotary Gas Meter?

Rotary gas meters trace their beginnings to the early 19th century. Back then, people used rotary meters as water pumps, but it wasn’t until the 1900s that the gas industry warmed up to them. Today, rotary piston meters have become a precise instrument designed to measure gas flow, typically in the 1,000 to 38,000 cubic feet per hour (CFH) flow capacity range.

Because of the way they are designed, rotary gas meters can handle higher volume and pressure than diaphragm meters. That makes them ideal for medium pressure application – 0-175 psi for regular pumps, but that can stretch to 0-1,480 psi for high-pressure models.

Rotary meters are a favorite of gas utilities for billing in industrial and commercial applications. Easy to install, maintain and test, rotary meters are reliable and offer the best accuracy range for low to high-capacity requirements.

How Does a Rotary Gas Meter Work?

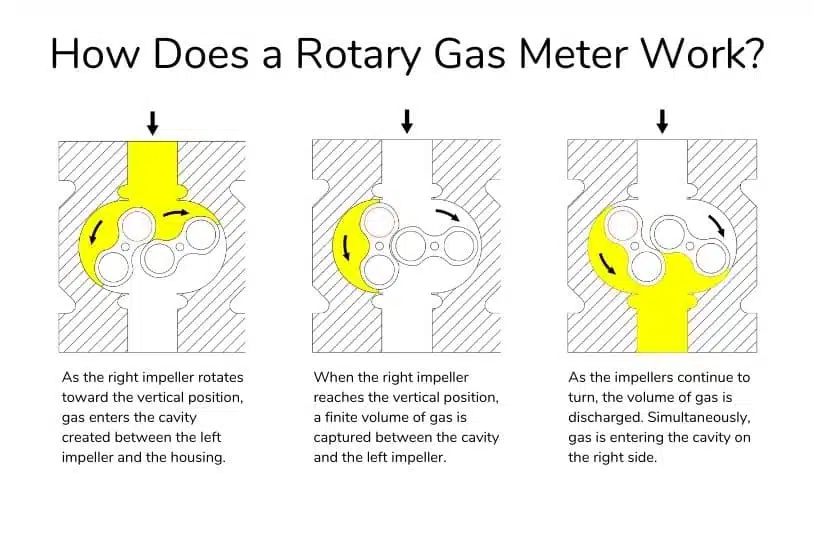

As mentioned previously, rotary gas meters work using the positive displacement principle. The rotary gas meter physically separates the intake into exact quantities and measures them individually, allowing precise total flow value recording.

The meter consists of a semi-cylinder cavity inside which are two rotating figure-eight impellers positioned 90 degrees in relation to each other by precision timing gears. These impellers rotate in opposite directions to each other due to the pressure drop across the meter created by downstream gas consumption. As it rotates, each impeller traps a finite and identical volume of gas. The final volume displaced by each revolution of the impellers is transmitted to a final readout module.

Difference Between Rotary Gas Meters and Other Gas Meters

A rotary meter uses the same principle as diaphragm meters but can measure higher volumes and pressure. However, a diaphragm meter has better turndown (~100:1) than rotary gas meters (~50:1).

Because of this, rotary piston meters are usually used in large, demanding industrial applications which diaphragm meters cannot handle.

While turbine flow meters and rotary meters can measure gases at extremely high pressures, turbine meters are a velocity type of meters. That makes them better suited to measuring the highest-pressure gas at the highest flow rate, although they also have a low turndown (~20:1).

Turbine gas meters measure gas indirectly, while rotary meters directly determine the gas flow rate by dividing the gas flow using the rotary blades.

Similarly, ultrasonic flow meters measure gas flow indirectly using sound waves. When gas flows through the pipe, there is a change in the reflected wave, which the meter records and uses to determine the volume of gas flow.

Vortex meters are pretty similar to rotary gas meters. Unlike rotary meters, vortex meters are used in industrial applications that require little custody transfer of gases.

Installation

To ensure optimal performance from any rotary gas meter, proper installation in accordance with the manufacturer’s recommendations is required. Rotary meters should be placed where they have the best chance of remaining uncontaminated for the best operation.

You can install the rotary gas meter by laying it either in the vertical or horizontal position. Before installing rotary gas meters, carry out the following pre-installation checks:

- Confirm the rotary piston meter is in perfect condition.

- Ensure the piping system of the gas meter is free from materials such as dirt and weld slag.

- Inspect the mounting flanges, ensuring they are parallel and well set apart.

- After performing a successful pre-installation check, install the meter using this procedure:

- Use the full flange gaskets.

- Tighten the flanges by using bolts and ensure you torque them using the correct value recommended by the manufacturer.

- Apply meter oil once done, as it will help with lubrication. Always use oil supplied by the manufacturing company to avoid damaging the impellers.

- Pressurize the installation at a slow rate of 35kPa per second until you achieve recommended pressure.

- Check for gas leaks.

Sizing

When installing a gas meter in a residential area, the gas providers must also consider the size of the gas meter they install in their customers’ houses. Installing a small gas meter in a household with many natural gas appliances may limit the amount of gas that a home gets.

A gasfitter sizes a rotary gas meter depending on the gas volume flow rate. For instance, if a home has a gas requirement of 300,000 BTU at ¼ psi, which translates to ~300 SCF/hr, select the smallest size meter that can handle ~300 SCF/hr. Most rotary gas meters will have sizes of 175 to 275 CFH.

Pros and Cons of Rotary Gas Meters

Pros

- Easy installation

- Handles extremely low or high pressures

- High rangeability, improving accuracy

- Robust design

- Resistant to external force impacts

Cons

- High maintenance cost

- Needs temperature and pressure compensation to get correct readings

Testing and Maintenance

If care and proper installation procedures are followed, rotary meters require very little field maintenance. Under normal operating conditions, a periodic check and maintenance of proper oil levels are all that is required. The time between checks can vary greatly, depending on utility requirements and/or the condition (cleanliness) of the gas. Oil that has become discolored due to dirt or emulsified due to water should be replaced. Once every 3 to 5 years is a normal or typical time interval.

A differential rate test on the rotary meter can be performed in addition to a visual check of the oil level and condition. The differential rate test is a reliable and acceptable method of comparing the performance of two variables.

There are various methods for testing the accuracy of a rotary gas meter, and all of them typically have an allowable error of +/- 1. Some of the tests include

- Bell prover test: The test compares the volume of the rotary meter to that of the bell, which is usually a known volume. Each bell travel determines the volume of gas passing through the meter and compares it to the volume registered in the meter.

- Transfer prover test: Determines the accuracy of the rotary meter by comparing the volume that flowed through the gas meter to that recorded on the master meter of the transfer bell.

Final Word – Why Choose a Rotary Gas Meter

Industry players prize the rotary gas meter for its high precision and ability to withstand extreme gas pressures and temperatures. These characteristics make them ideal for large, demanding industrial applications. In addition, rotary gas meters are an affordable measuring solution specifically for utility billing, submetering and custody transfer applications.

If you’re in the market for a rotary gas meter, Norgas carries Romet rotary gas meters which are among the most reliable measuring gas meters on the market. We have more than 34 years of experience in the gas supply industry, so we have the expertise to advise you on the right gas regulators and valves to match your rotary gas meter.