How to Select a Gas Pressure-Reducing Regulator

Operating a natural gas appliance requires carefully balanced gas pressure. If natural gas comes into the appliance too fast at too much pressure, the appliance might explode. If the pressure is too low, the appliance won’t work. Gas pressure-reducing regulator selection is an exact science that can take hours to understand when poring over manufacturing sizing charts. Experts in the industry can help you understand the differences and assist with selecting a gas regulator that fits your needs.

Applications of Gas Pressure Reducing Regulators

Natural gas regulators are used in many systems, but their key focus is based on how fast gas is required to be released to the appliance. High-pressure regulators control gas furnaces, commercial grills, generators, and heaters in warehouses and barns. Low-pressure regulators are often used with smaller indoor or patio heaters, gas-fired appliances, camping stoves, and greenhouse heaters. When dealing with gas regulator sizing, it’s important to understand the type of application and any special needs before selecting a gas regulator. Make sure to have all the information you need.

Types of Natural Gas Regulators

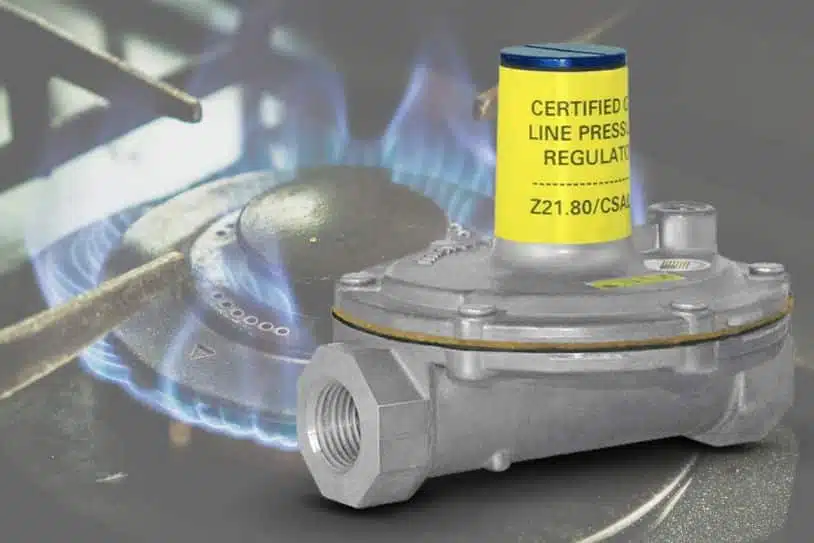

A gas regulator consists of three main elements. The restricting element controls the flow of gas. It opens and closes as necessary. The measuring or sensing element adjusts to the downstream pressure. The loading element pushes the restricting element open as demand increases. These three functions work together to ensure that supply and demand are equal in the system to make the appliance work safely and efficiently.

There are four basic types of natural gas regulators:

- Service regulators decrease pressure from the service line to the desired delivery pressure.

- Line gas regulators control pressure between the service regulator and the appliance regulator.

- Appliance regulators control the gas pressure into an appliance.

- Pressure regulators control the pressure of a specific section of a pipe system.

Why Is the Gas Regulator Important?

The gas regulator offers many benefits, the main one being safety. If a user were to allow natural gas to flow at a dangerously high pressure, it could cause an explosion. If the pressure is too low, the appliance won’t work the way it is supposed to. The regulator manages the supply and demand to protect the people involved in operating the system.

The gas regulator also controls the efficiency of the system. A system that only needs 45 psig (pounds per square inch gauge) does not operate at higher pressure levels. Maintaining steady pressure ensures that materials are utilized effectively and accurately. Using natural gas regulators also allows for flexibility in the design of a network.

Factors to Consider When Selecting a Gas Pressure Reducing Regulator

When choosing a gas regulator, you have to take into account multiple aspects of the system. Below is a list of the most important aspects to consider.

Type of gas

While natural gas is the most common type of gas that uses regulators, propane or other types of gases can also be regulated. The first step is to be very clear about what type of gas you are working with.

This is because each type of gas has unique characteristics in terms of chemical composition, corrosive properties, impurities, flammability, temperature, etc. In some cases, special attention must be paid to the selection of materials that will come into contact with the gas being used.

Inlet pressure

You will need to know what the gas pressure is, coming into the regulator. The maximum and minimum Inlet pressure determine the pressure rating for the body inlet, the orifice pressure rating and size, the main spring (for pilot-operated regulator) and the regulator size. Significant variations in inlet pressure can affect the controlled pressure accuracy, the regulator capacity and the regulator style (direct-operated or pilot-operated).

Outlet pressures

You must know the desired outlet pressure to select the correct gas regulator. The outlet pressure helps determine the spring requirements, the casing pressure rating, the body outlet rating, the orifice rating and size as well as the regulator size.

Capacity

This is measured as the gas flow or flow rate, generally measured as BTU/hour or cubic feet/hour. The required flow capacity influences decisions such as the size of the regulator, the orifice size and the regulator style (direct-operated or pilot-operated).

Other Considerations for Gas Regulators

For natural gas pressure-reducing regulators to operate effectively and safely, there are a few other factors to assess before your final gas regulator selection.

Pipe Size

Pipes generally come in sizes ½-inch to 4-inches, which impacts the flow rate of the gas. In many applications, we want to ensure that the regulator reaches its full capacity. To achieve this, we need to ensure that the outlet piping is larger than the regulator.

End Connection

Natural gas regulators come with different connections at the end. Depending on the application, you may need pipe threads, flanged, or butt weld connectivity.

Shutoff Capability

This refers to the type of disk material to get the desired shutoff capability. Some materials shut the regulator tighter than others.

Accuracy

Even small variances in pressure can cause inaccurate readings. The greater accuracy you need for safety or efficiency, the more control you may need in the regulators. This can be achieved by selecting regulators with less droop, or proportional band or offset.

Required Materials

The application generally determines the material the regulator is made from. The most common materials are aluminum, cast iron, steel, stainless steel, bronze, or brass, but special materials can be used when required.

Overpressure Protection

Deciding whether you need an external or internal relief valve often must be done at the point of purchase, not after you’ve installed the regulators.

Stroking Speed

Natural gas regulators operate at different speeds. Generally speaking, direct-operated regulators are faster than pilot-operated regulators.

Control Line

If the system needs control lines, this should be developed into the design specifications.

Altitude

The atmospheric pressure is impacted by altitude, so this must be taken into account when installing a regulator.

Location

If the regulator is located indoors, you may need additional components that will serve to ensure safe and efficient operation.

Noise

If noise or vibrations are an issue, you may need to choose a specific regulator that generates less noise or vibrations.

Price

When selecting a gas regulator, you should consider the initial purchase cost, but also the additional costs of installation and maintenance. A low-cost regulator may be more expensive in the long run.

If you are unsure about the specifications or elements that you’re working with, ask for help with the selection of your gas pressure-reducing regulator.

Seek Professional Advice to Select the Right Gas Regulator

To make your appliance or system work most effectively and efficiently, it helps to consult industry professionals who know the capabilities and drawbacks of different gas regulators. Understanding all the minor details of the system can help you understand why sizing a gas regulator is so precise.

In most jurisdictions, local authorities will require an inspection before the appliance can be turned on, so it is vital that the right pressure-reducing regulator is selected. You will want to have all the information for the regulator to make sure it does the job. If you can provide the parameters for the job, the regulator can be accurately sized. Remember, if the parameters change, a different regulator may be required, even for small changes to the design.

Norgas has a wide variety of natural gas regulators in stock. We can also design a custom solution for your application. Whether you are looking for gas regulators, gas valves or gas meters, our experts are here to help.