5 Types of Natural Gas Pressure Reducing Regulators

There are many different types of equipment and appliances that require pressure regulators to keep pressure levels controlled at all times. Natural gas regulators are vital pieces of equipment that ensure proper gas flow and performance of the appliance or equipment while protecting it from overpressure. Gas regulators normally fall under one of the two following categories: pressure reducing regulators or back pressure regulators. Below, we will walk you through the basics of the different types of natural gas pressure reducing regulators.

About Pressure Reducing Regulators

A pressure reducing regulator is located at the front end of the system before the pressure sensitive equipment. This valve is usually open, and it’s used to reduce or regulate higher pressure levels that could be problematic. When you use a pressure reducing regulator, the gas flows at a consistent and predetermined rate, which improves safety and makes the process more predictable. Pressure reducing regulators are often used as a suction controller on gas compressors or for re-circulation on gas compressors.

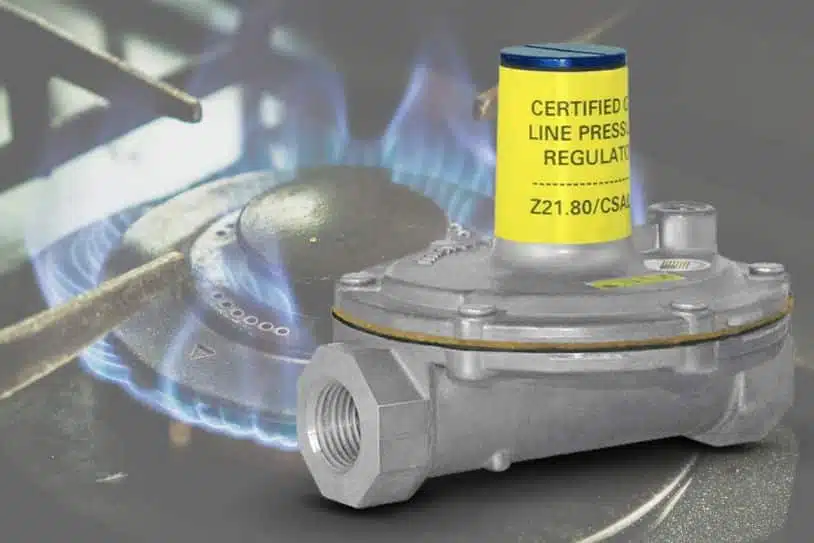

Most pressure reducing regulators are tested and certified by CSA and ULc, so you can feel confident they will be safe and provide you with the results you need.

Types of Natural Gas Pressure Reducing Regulators

Appliance Regulators

Those designing appliances or seeking to make repairs on appliances are likely looking for appliance regulators. These are natural gas regulators found in residential, commercial, and industrial natural gas equipment of various sizes. Appliance regulators are the last regulator in the line, and so they may be responsible for dealing with very tiny, precise flows of natural gas for the pilot load. Or, in larger industrial equipment, these regulators may still be dealing with large flows of gas for the main burner.

Line and Service Regulators

Often next in line, these regulators are installed before the appliance, regulating the supply line that is servicing the appliance and ensuring inlet pressure is ideal. Beyond natural gas, these regulators are used for all kinds of non-corrosive gases. For your purposes in natural gas, you can get a line or service regulator that is ready for use in residential, commercial or industrial settings.

When it comes to choosing a line and service regulator, look for ones with the right options to fit your application, such as internal relief valves, ventless and made for indoor use etc.

Pilot Operated Regulators

In applications where you are dealing with high capacities of natural gas and want to keep it highly pressurized, with as small an outlet pressure drop as possible, pilot-operated regulators are right for you. The pilot adjusts the pressure in these regulators, and they work with very high precision. Technically, these are two independent regulators combined together with a smaller pilot. They work by harnessing the power differential across the regulator.

Direct Acting Regulators

Direct-acting regulators are all about improving performance. They are insensitive to inlet pressure changes thanks to their balanced design. They deal with high capacities and respond quickly to capacity changes. To install them, you will also need a downstream sensing line.

High-Pressure Regulators

As you would imagine, high-pressure regulators are for high-pressure applications. They can be used for compressed gases, corrosive gases and non-corrosive gases, making them a great choice for a wide range of applications. It is especially important to choose the high-pressure regulator which has the right approvals for your use.

What About Back Pressure Regulators?

Back pressure regulators also work to control pressure levels, but they have a slightly different role than pressure reducing regulators. A back pressure regulator is usually installed downstream of another regulator and is designed to relieve excess pressure if the main regulator fails. Normally closed, a back pressure regulator is used to keep upstream pressure consistent in the event that the inlet pressure increases too much.

Deciding between a pressure reducing regulator and a back pressure regulator will therefore depend on the specifics of the situation. It is possible to use both types if you need balanced pressure throughout a particular application.

Learn more: Back Pressure Gas Regulator vs. Pressure Reducing Gas Regulators

In Conclusion

Appliance regulators, line and service regulators, pilot-operated regulators, direct-acting regulators and high-pressure regulators are all types of pressure reducing regulators used in natural gas distribution. While some are better suited to certain applications, they all have the function of maintaining a constant outlet pressure at certain points in a given distribution system. As for back pressure regulators, they are used to protect the system by venting excess pressure in the event that the main regulator fails to close.

Choosing the right pressure reducing gas regulator for your application can be complex and often requires expert advice. Access to a trusted supplier with a proven track record will ensure you have the right natural gas regulator every time.

Norgas provides natural gas regulators, valves and meters to customers across Canada. We carry many types of natural gas regulators in stock and can also design a unique solution to meet your unique requirements. Find the best type of regulator for your application by contacting our experts today!