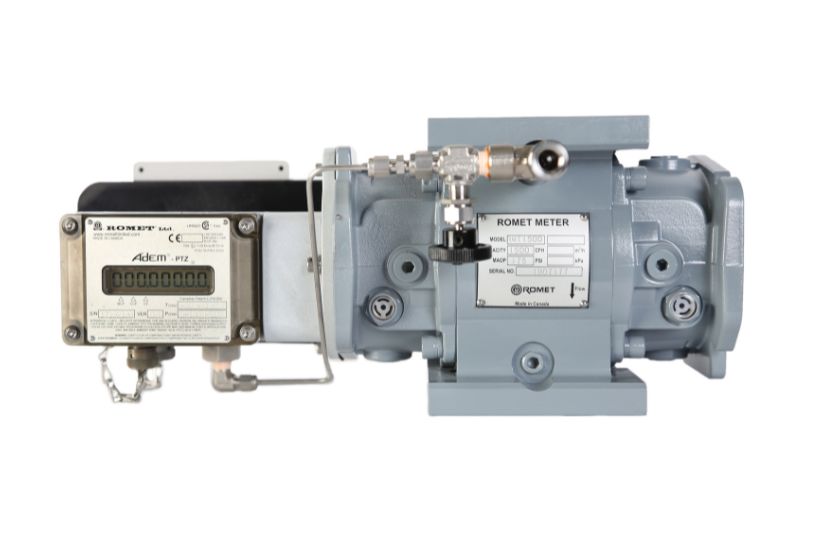

Romet Rotary Meters: Installation & Maintenance Tips

Romet rotary gas meters are renowned for their precision, reliability, durability, stability, and high turndown. In this article, we provide an overview of the Romet rotary meter installation and maintenance guide. For additional information, please refer to the complete RM Meters Installation & Maintenance Manual.

About Romet Rotary Meters

Romet rotary gas meters provide accurate measurements with a range of +/- 1% to comply with the ANSI B109.3 standard. They can handle a higher flow capacity of up to 38,000 cubic feet per hour, making them more reliable and superior to diaphragm gas meters. One of the unique features of this type of meter is that an advanced electronic module can be mounted directly on the meter to provide more accurate measurements in the event of pressure and temperature fluctuations. Easy to install, maintain and troubleshoot, Romet rotary meters are among the best-selling rotary meters.

Pre-Installation

Even though RM gas meters are renowned for their rugged design and durability, improper packaging, transportation, or handling can cause irreversible damage to the meter. The pre-installation stage can help installers inspect the gas meter for possible damage, missing hardware, and other issues.

Here are vital measures to take before installing a Romet rotary meter:

- Check the meter for possible damage caused by improper handling or transportation, and consult the manufacturer or distributor in case of noticeable defects for further examination.

- Blow into the meter inlet to test the impellers. They should rotate freely before gradually stopping after some time.

- Remove all foreign materials and obstructions from the meter piping before installation.

- Ensure the mounting full-faced pipe flanges are at the appropriate distance apart, are level, and correctly aligned.

- Ensure adequate spacing between the flanges, piping, and RM meter.

- Check if all the correct hardware is available, including the flanges, gaskets, bolts, and washers, for proper Romet rotary meter installation.

- Return the rotary gas meter to its protective container before commencing the installation.

Installation

Romet rotary gas meters are easy to install if the proper tools and equipment are available. The most common tools and accessories required for Romet rotary meter installation include the following:

- Adjustable torque wrench (5-40 in-lbs range)

- 9/64” Hex wrench

- 5/32” Allen wrench

- Flat blade screwdriver

- Light-grade machine oil

As much as you can install the RM gas meter horizontally (side inlet), vertical installation (top inlet) is ideal for easy expulsion of contaminants and to prevent possible damage. Here are the steps to install a Romet rotary gas meter:

- Remove the RM gas meter from its protective container.

- Gather all required hardware accessories, including bolts, washers, gaskets, and flanges.

- Join the meter inlet with the gas supply and mount it in the correct gas flow direction (as the meter arrow indicates).

- Remove the piping strain to prevent the impellers from binding.

- Use pipe supports and full flange gaskets as required.

- Level the RM gas meter to within 0.25 inches and ensure it is higher than the outlet to avoid the accumulation of contaminants.

- Tighten the flanges in a cross pattern (X) with a maximum torque value of 20 ft-lbs. Overtightening the bolts can damage the meter.

- Connect the connecting nipples or connectors to the meter’s index.

- After installation, open the front end cover and remove the filling plug to access the oil reservoir.

- Add a Romet-approved meter oil to the appropriate reservoirs, including the magnetic housing and thrust cover. Applying non-approved oil may void the warranty.

- Apply a sealant around the plugs to prevent leaks.

Note: Oil volumes differ depending on the meter model and orientation. Check the oil level gauge not to under or overfill the reservoir.

Post-Installation

The post-installation stage checks if the RM rotary gas meter functions as desired. It entails starting up and pressurizing the meter slowly to check for leaks and other possible issues. Rapid pressurization can lead to an internal over-speed, eventually damaging the meter.

Here are vital post-installation steps for Romet rotary gas meters:

- Turn on the gas supply slowly at 35 kPa or 5 psig while checking for leaks.

- Open the outlet gas and bypass valves.

- Open the inlet gas valve partially until the meter operates at low speed.

- Check the index drum for movement to verify that gas flows in the correct direction.

- Allow the meter to run for a few minutes and listen for unusual knocking sounds.

- If strange sounds are present, depressurize the meter and check for torsion problems or piping misalignment.

- Install a correctly sized venture flow nozzle downstream to protect the meter in case of instant on-off gas loads.

- Once resolved, slowly open the inlet and allow gas to flow through the meter until the valve opens entirely.

Romet Rotary Meter Maintenance

Romet rotary meters require proper care and maintenance to ensure they function at maximum capacity and deliver accurate measurements. RM gas meter maintenance also prevents costly repairs and replacements.

Here are a few Romet rotary meter maintenance tips:

- Under favorable operating conditions, always inspect the meter once every 3-5 years.

- Inspect the front end cover twice yearly to check the oil condition and level.

- Ensure the oil is clear and at the correct gauge level.

- Change or fill the oil to the required level as necessary.

- Before removing the meter from the pipeline for cleaning, drain all the oil from the reservoir.

- Windmill the impellers to expel visible dust or dirt from the meter.

- Use 150ml of a non-flammable solvent to flush out contaminants.

- Use compressed air to dry the inlet after cleaning the meter.

If the RM meter is running unusually “slow” or has halted due to contamination from the gas stream, follow the instructions in the Romet Shop Manual to service the meter. Before taking the meter off the installation, make sure to drain all the oil to prevent it from entering the measurement chamber while handling. Once the meter servicing is done, conduct a differential pressure or proof test to verify that the meter is clean and functioning correctly.

Conclusion

Romet rotary gas meters are rugged, accurate and reliable meters designed to measure natural gas and most clean, dry gases. Proper installation and maintenance are essential to ensure the proper operation and accuracy of this type of gas meter. Therefore, following the pre-installation, installation and post-installation steps outlined in the RM Meters Installation & Maintenance Manual is very important. Failure to do so may result in costly repairs or replacements.

Norgas supplies gas meters across Canada, including Romet rotary gas meters. Contact our experts if you have questions about RM rotary gas meters or need help choosing the right gas meter for your application, whether it’s a diaphragm gas meter, a rotary gas meter or a turbine flow gas meter.