Types of Natural Gas Meters: Traditional and New Technologies

Gas metering devices are critical for controlling or measuring the flow of gases in pipes in a wide range of applications across the residential (utilities), commercial, and industrial sectors. Depending on the application type and required level of accuracy, you may have to choose from different types of gas metering devices, including traditional gas meters or newer technologies.

Read on for an overview of the various types of gas metering devices. Equipped with this information, you will be able to make the best choices for your applications.

Gas Meter Mechanisms

Each natural gas meter has its own benefits and limitations and excels in different types of applications. While the external appearance of most gas meters may be quite alike, they work on different types of mechanisms:

- Differential Pressure based: Orifice meters

- Motion Mechanics based: Coriolis meters

- Positive Displacement based: Diaphragm gas meter and Rotary gas meters

- Thermal Dispersion based: Thermal mass flowmeters

- Variable Area based: Rotameter gas meters

- Velocity based: Turbine gas meter, ultrasonic flowmeters and vortex gas meters

Note that most types of gas meters may come with the option of analog displays or digital indicators.

1. Diaphragm Gas Meters

Learn more about diaphragm gas meter.

2. Rotary Gas Meters

Learn more about rotary gas meters.

3. Turbine Gas Meters

Learn more about turbine flow meters.

4. Orifice Gas Meters

A type of differential pressure meter, orifice meters infer the rate of gas flow by measuring the pressure drop over an obstruction inserted in the flow. Besides their use in custody transfer of natural gas, orifice gas meters are the most popular method of flow measurement for industrial applications as they have no moving parts and are easy to field service. Orifice plate meters offer a practical turndown ratio of 3:1.

5. Rotameters

Used in the process industries for monitoring gas at plants or in labs or filtration loading, rotameters do not need any external power, making them a great fit in hazardous locations with flammable gases. Rotamers offer an extended measurement range with reasonable accuracy in low and medium rates. Additionally, they are inexpensive and highly resistant to chemical action, as well as thermal shock.

4 Types of New Technology Gas Meters

1. Coriolis

Measuring the mass of gas flowing through the meter by a physical principle called the Coriolis effect, Coriolis gas meters can handle a wide range of flow rates and have the highest accuracy of mass flow measurement.

2. Thermal Mass Flow

Also known as immersible mass flow meters or thermal dispersion meters, thermal mass flow meters comprise a set of instruments that measure the total mass flow rate for gases through the heat convection from heated surfaces to the flowing gas. They excel at many applications, including energy management, natural gas, biogas, flare gas, airflow and combustion control, and offer a turndown ratio of ~1000:1.

3. Ultrasonic

A type of velocity-flow gas meter, ultrasonic gas meters use ultrasound to measure the speed of gas inside the pipes. One of the largest applications is in the custody transfer of natural gas, where they are used throughout the network in gathering, transmission, as well as distribution. They excel in measuring the flow of steam and gases, and most ultrasonic meters have a turndown ratio of 50:1.

Source: Honeywell Smart Energy

4. Vortex

Vortex meters operate under the vortex shedding principle and measure volumetric gas flow. They are ideal for accurately measuring compressed air or steam. Since they have no moving parts, they offer high reliability and stability and do not need costly maintenance or repairs. Vortex meters are popular tools for metering, measurement, and control of gas or steam processes in power or energy facilities, as well as heavy industrial applications.

Find the Right Type of Gas Metering Devices for Your Applications

Achieving accurate gas measurement or metering is a top priority for many industrial, commercial, and residential applications. However, despite the wide choice in types of gas meters, no meter technology is perfect. In order to make the right choice for your applications, consider the following:

- Purpose: Do you need to measure volume or are you looking to monitor the flow of gas in a process?

- Type of gas: Is it a mixture or a clean, single gas? What is the flow range, pressure range and temperature range of the gas?

- Installation location: Are there any environmental interferences at the location? What is the pipe size?

- Type of measurement: Volumetric flow or mass flow? Do you need a flow meter totalizer?

- Budget: What is the impact of the various costs (purchase, installation and maintenance) and the device life expectancy on your total cost of ownership?

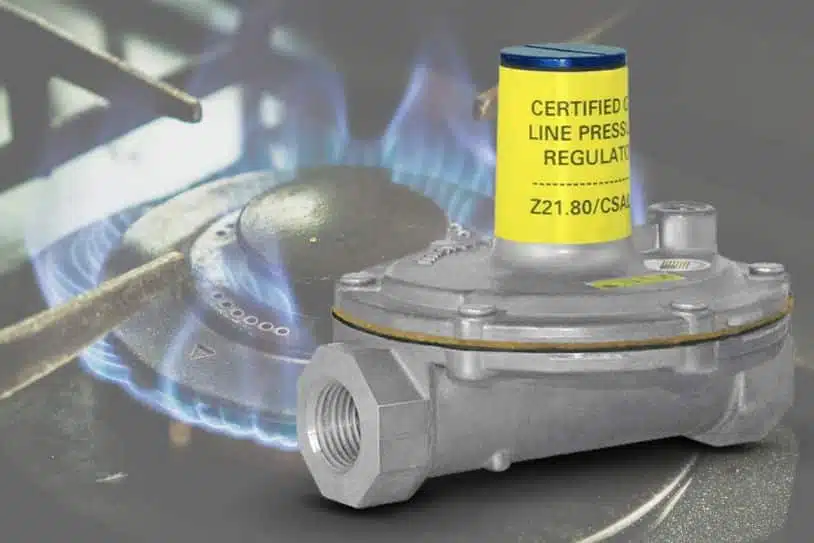

Norgas Controls specializes in the regulation and measurement of natural gas across Canada. We carry different types of natural gas meters including diaphragm, rotary, and turbine flow meters as well as other products dedicated to the gas industry such as gas regulators and valves. Our products are primarily used in submetering, utilities, commercial and industrial applications and we can help you find the right solution for your application.

Contact us to get more information on our products and to receive advice from our team of experts.