Lubricated VS. Non-Lubricated Plug Valves

There are two types of plug valves: lubricated and non-lubricated. This guide explains the difference between these two main types of plug valves. Learn the advantages, disadvantages, and applications of each so that you can answer your customers’ questions about this simple but highly effective equipment.

What is a Plug Valve?

First, a brief intro on plug valves. Plug valves are on-off valves used in a wide variety of applications. Users choose them for frequent operation tasks, and they are quarter-turn valves. There are three port patterns: regular, Venturi, and short. You can learn more about plug valves by reading our previous article: What is a Plug Valve and What is it Used for.

Lubricated plug valves and non-lubricated plug valves each have their uses, described below.

Non-Lubricated Plug Valves

Non-lubricated plug valves have a sleeve or liner installed in the cavity. The tapered plug wedges the sleeve against the plug body. In this way, the non-metallic sleeve decreases friction during operation. These gas plug valves require little maintenance, and their compact size makes them convenient to pack along with other equipment.

Advantages of a Non-lubricated Plug Valve

- Few moving parts to reduce maintenance

- Can service while installed

- Fast opening, closing

- Minimal resistance for liquid, air, or gas flow

- Leak-proof

- Contact with sleeve discourages the accumulation of debris

- Can improve seal with injected sealant (or replace sleeve)

- Available in multi-port design

Disadvantages of a Non-lubricated Plug Valve

- Needs greater actuation force (high friction)

- Larger valves — NPS 4 (DN 100) and higher — require actuators

- Tapered plug means reduced port size

- More expensive than ball valves

Applications of a Non-Lubricated Plug Valve

- Nearly universal: Air, gas, and vapor applications

- Oil or natural gas piping

- Coal slurries, mineral ores, and mud

- Sewage applications

- Vacuum to high-pressure

Lubricated Plug Valves

A lubricated plug valve has a central cavity that’s closed at the bottom. Additionally, a sealant injection fitting sits at the top to inject the sealant into the plug cavity. Then, a check valve located below the injection fitting keeps the sealant from reversing direction. During operation, sealant moves from the centre cavity to lubricating grooves via radial holes.

If the sealant washes away, it could contaminate the medium, break the seal between the body and plug, and cause leakage. Therefore, it’s very important to match the sealant with the application (air, liquid, or another medium).

Advantages of a Lubricated Plug Valve

- Creates a renewable seal between body and plug, minimizing internal leakage

- Protects surfaces from corrosion

- Lubricates surfaces, reducing the necessary actuating force

- Greater lubricant pressure prevents solids from entering the plug cavity

Disadvantages of a Lubricated Plug Valve

- High risk of lubrication contamination (reduced by using a compatible lubricant)

- More moving parts than a non-lubricated valve

Applications of Lubricated Plug Valve

- Pressures over 2500 psi (17250 kPa)

- Air

- Gas

- Acids

- Water

- Alkalis

- Steam

- Oil and fuel

Sealant/Lubricant Requirements

When using a lubricated plug valve, it is essential to match the sealant with the medium flowing through it. Otherwise, you could contaminate the fluid. The sealant also must be able to withstand high temperatures if required by the application.

Plastic sealants are used to lubricate plug valves. A suitable sealant has the following qualities:

- Proper elasticity

- Resistance to solvents and chemicals

- Ability to form an impervious seal under pressure

- Anti-corrosive

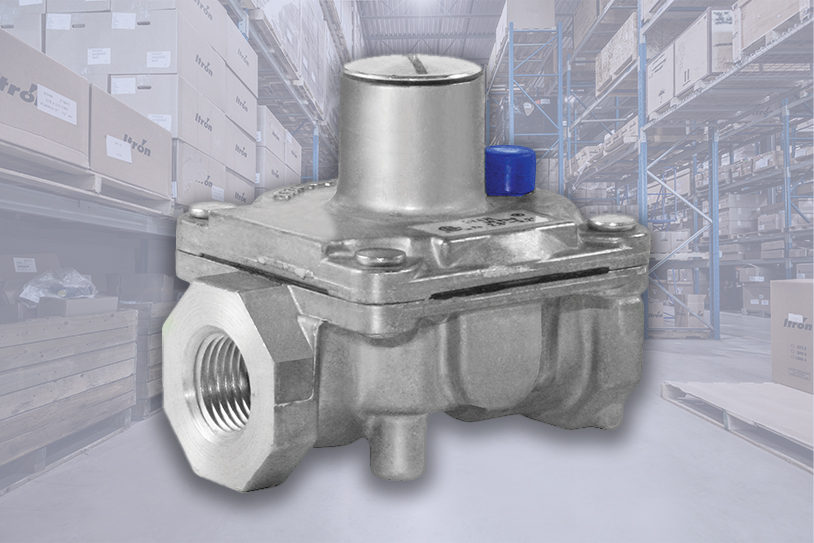

Example of a Cast-Iron Lubricated Plug Valve

Gas plug valves, such as the Norgas cast-iron lubricated plug valve, boast a simple design. Cast-iron valves come in handy as shut-off valves in light industrial or commercial applications. Your customers will love the easy maintenance — you can perform maintenance without removing them from the line.

The Norgas Control cast-iron lubricated plug valve works particularly well for manual gas shut-off.

Here are three of the most important features:

- CSA 3.11 certified to withstand 125 PSI

- Handles temperatures as low as -40 C

- Ideal for outdoor use

The Hattersley lubricated plug valve has a beautifully simple design. With a specially formulated lubricant, it forms a nearly leak-proof seal.

Here’s how it works:

- In the closed position, pressure is applied.

- This forces the plug downstream.

- Contact between the body and plug with the sealing lubricant in between forms a leak-tight connection.

- The sealant lubricates and protects the surfaces, reducing corrosion and wear and tear.

- Minimal maintenance includes re-lubrication with valve sealant.

The specifications of the Norgas cast-iron lubricated plug valve give you and your customers an idea of what to expect in this type of plug valve:

- Gearing: Available with gear operator options

- Routine Maintenance: The frequency of relubrication depends on the pressure, temperature, and frequency of operation, among other things.

- Lubricant / Sealant Options: Match the sealant to the application. Remember that you can always call Norgas with any questions. Generally, sealant differentiation includes oil, gas, and asphalt. Lubricants often come in a stick and cartridge dispenser.

Key Takeaway about Lubricated and Non-Lubricated Plug Valves

When you are looking for sturdy gas plug valves to control the flow of gas, oil, and other media, the choice between lubricated versus non-lubricated plug valves comes down to the type of application.

The information above includes specifications for an example of a lubrication valve to help you understand the way these products work. Each type of plug valve has certain advantages and disadvantages. If you or your customers have any questions, our customer service team is happy to explain individual products.

Norgas Controls has been supplying the Canadian market with quality regulation and measurement products such as gas regulators, gas valves, and gas meters for over 35 years. Feel free to contact us for more information about our gas plug valves or any other product we carry. Our team of courteous, knowledgeable support staff will be happy to assist you.