What is a Plug Valve and What is it Used for

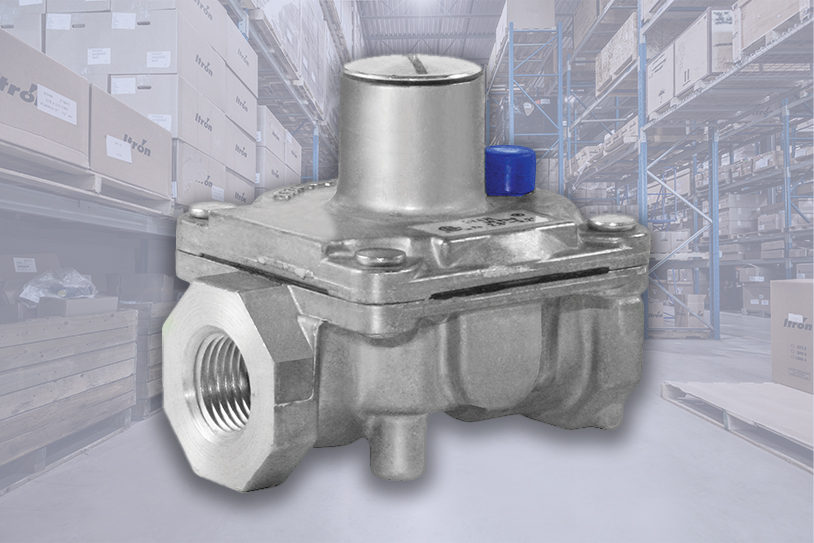

For any sector that relies on hydraulic systems in their operations, gas plug valves are an essential component for the smooth and efficient running of the systems. Usually available in cylindrical or conical shapes, plug valves are quarter-turn manual motion valves used for stopping or starting the flow of fluid. They offer on-off, diverting, as well as basic moderate throttling services.

Read on for an overview on plug valves, along with their types and applications.

How Does a Plug Valve Work?

A plug valve is based on a plug with a hollow passage in the valve body. The quarter-turn motion creates an alignment between the pipe and the hole, leading to an open state. When turned to a 90-degree angle from the open position, the valve sits across the pipe leading to a closed state.

See the animated video below that explains how a plug valve works.

Plug valves are available in a variety of different styles and port openings through the plug.

- Two-Way Plug Valves: The design allows for a closure element in the middle (a plug and a sleeve), along with a straight through, two-way service for the open and close function.

- Three-Way Plug Valves: These valves include a third port, which typically sits at a right angle from the inlet. These plug valves can help in diverting flow (entry from inlet directed between one or both outlets) or combining flow (entry from the two inlets channeled into a single outlet).

What is a Plug Valve Used for?

Plug valves are an excellent option for many commercial and light industrial applications, including directional flow control, handling of gas or liquid fuels, regulating fluids with suspended solids, such as slurries, or handling low-pressure, low-temperature services. Due to their smooth design, inline maintenance capabilities, leak-tight service, minimal resistance to flow, and multi-port design options, gas plug valves find application across a multitude of sectors and systems.

What are the Different Types of Plug Valves?

-

Lubricated Plug Valves

Highly suitable for dirty upstream applications, the cast iron lubricated plug valves can handle abrasive or corrosive materials and do not get clogged. These plugs require frequent resealing for maintaining optimum effectiveness.

-

Non-Lubricated Plug Valves

Used in settings that prioritize low-maintenance applications, non-lubricated plug valves include elastomer sleeved, lift-type, and fully lined plug valves.

-

Expandable Plug Valves

These valves comprise multiple components and a complex rotation motion that helps in avoiding wear or abrasions to the seals. They are a good fit for preventing product contamination in applications that do not require double isolation.

-

Eccentric Plug Valves

Ideal for applications that need a higher seating force and minimal friction from open to closed position, eccentric plug valves find a place in a wide range of isolation or flow control systems. This includes sewage, sludge and slurries, air, and other services.

Advantages and Disadvantages

Besides being compact and using up less space, gas plug valves offer the following advantages:

- Flow Regulation – Tight shut-off, quick opening and low-pressure drop.

- Fire-safety and Durability – Reduced likelihood of corrosion or erosion as the actual plug and body seating surface do not get exposed to the line fluid.

- Versatility – You can use plug valves with large flow rates as well.

A few disadvantages of plug valves are:

- They are not suitable for throttling applications.

- They require greater force for actuation due to high friction.

- They present the possibility of galling.

- The tapered plug design basically leads to a reduced port.

Learn more about plug valves by reading our next article: Plug Valves vs. Ball Valves: What are the Differences?

Find the Right Plug Valves for Your Application

Whether it is gases, liquids, non-abrasive slurries, fuel gas piping systems, chemical industries, fly ash applications, or vacuum to high pressure applications, plug valves play a key role in an extensive range of applications and industries.

At Norgas, our team of experienced professionals has a deep understanding of the HVAC, propane, industrial, and combustion markets. We can help you find the best gas plug valves among reputable brands such as Milliken Hattersley plug valves or flow regulation solutions for your specific project or application.

Contact us at 888-427-7347 for more information on our gas plug valves or if you have questions about our other products such as our gas regulators and gas flow meters.