5 Overpressure Protection Methods in Natural Gas Distribution Systems

Overpressure in natural gas systems can happen if your regulator has a diaphragm or mechanical failure or when there is a foreign object between the seat and valve. It also follows using an undersized or blocked vent opening. In all these instances, the inlet pressure will flow downstream when the equipment or piping has a pressure that is above its predetermined values. This might damage your appliances and lead to large unstable flames. Overpressure protection methods (OPP) prevent appliance or pipe pressures in a natural gas system from exceeding the predetermined value to ensure safety in case the pressure regulator fails or malfunctions. Here are some methods of protecting natural gas distribution systems from overpressure.

Types of OPP Methods Used To Protect Natural Gas Systems Against Overpressure

Below are five OPP methods used to protect natural gas systems from overpressure;

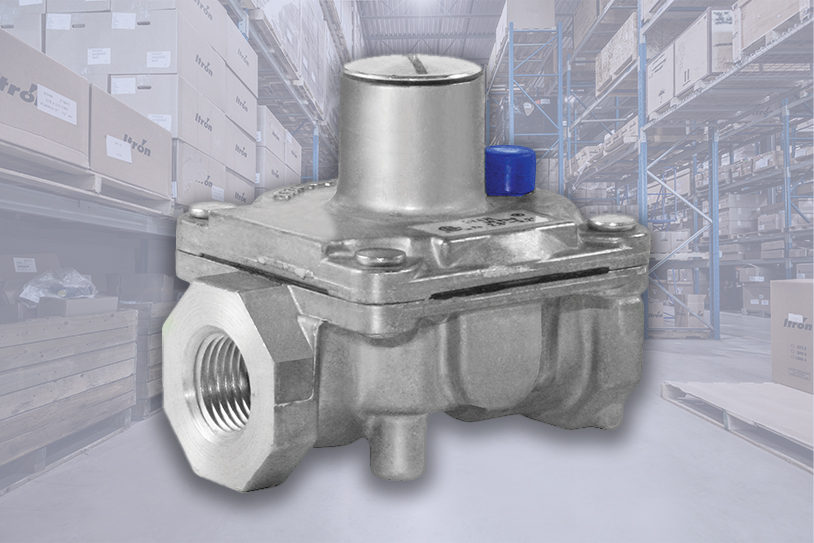

Pressure Relief Valves (PRV)

A relief valve will vent process fluids to the environment when the pressure in a natural gas system exceeds the predetermined value. When the valve senses that downstream pressures are exceeding a set point, it automatically opens to relieve the excess pressure. This is the most common overpressure protection method used in medium and low-capacity applications.

There are four types of relief valves, including:

- Pop-type relief valve

- Internal relief valve

- Pilot-operated relief valve

- Direct-operated relief valve

The pop-type relief valve is the simplest of the four and often opens wide when the pressure in a system exceeds a set margin. Pressure relief valves are considered the most reliable OPP options since they do not risk getting blocked by foreign objects when working. Moreover, they do not reduce the capacity of the regulator being protected and act as their own alarms when venting.

Unfortunately, when a relief valve blows, this could be a hazard for objects and people within the surroundings of the valve. In high population densities, a noisy venting valve can become a nuisance. Moreover, it should be individually sized according to a system’s maximum inlet pressure.

Worker/Monitors

In high-pressure drop or volume systems, a control valve that functions as a worker/monitor is preferred. The control valve, in this instance, is typically a rotary ball type because of its low restriction when open and high inherent capacity. With this overpressure protection method, you will need a pressure-sensing device because a control valve is not self-operated. You also need a controller that will vary the valve’s position according to a system’s pressure.

With a worker/monitor valve, there is no venting to the atmosphere, so you can use this overpressure protection device in places with many people without causing a disturbance. Furthermore, the valve is easy to maintain, has accurate control, and is cost-effective. However, a worker/monitor valve is prone to blocking, so the use of strainers or filters is necessary to prevent blockages. The valve also has a higher upfront investment compared to a relief valve.

Series Regulation

Like the worker/monitor valve, series regulation is OPP by containment. It entails using two natural gas regulators within one system. The first maintains the inlet pressure flowing to the second one, which is set within the highest allowed operating downstream pressure. With series regulation, the downstream pressure will not exceed the set safe maximum value if one of the regulators fails. This OPP method is often used when reducing gas pressure to one that is significantly lower than a distribution system’s highest allowable operating pressure.

With series regulation, your OPP will not be a public nuisance, and there is no hazard from venting gas into the atmosphere. However, the second gas regulator will have a low-pressure differential for generating flow since the system’s intermediate pressure should be lowered to one that is safe for the downstream. Thus, you might have to significantly increase the second regulator’s size to maintain a sufficient pressure differential.

Slam-Shut Valves

Slam-shut valves can be used as standalone devices or as part of pilot-operated regulators. The valve’s internal mechanism will unlatch while its isolation flapper closes when the valve senses a pressure that exceeds a set point. The flapper will remain closed to stop the gas flow until you manually reset the valve. The slum-shut valve will thus provide OPP for your system and keep it shut until you identify and correct the cause of overpressure.

The main benefit of a slam-shut valve for OPP is that it provides dual security in that it also offers under-pressure protection. If your gas appliance has a lower pressure than its set point, the gas might not ignite. If this happens, gas might accumulate in the atmosphere and ignite to cause an explosion. As such, under-pressure protection is as crucial for your system as OPP. Note that the shut-off feature in slam-shut valves can also be triggered by debris temporarily lodged in them.

Relief Monitor

In natural gas distribution systems with up to 10,000 cu ft per hr, you can use a monitor and an internal relief valve. The relief capacity of this overpressure protection device is limited to prevent the excess venting of gas. In so doing, the monitor is quickly brought into operation. This causes a fall of downstream pressure, sometimes to below 1 psg.

In a relief monitor, downstream pressure protection will be maintained even in excessively high inlet pressures, and the disturbance to the public because of vented gas is kept to a minimum. Moreover, a relief monitor does not need manual resetting.

In Conclusion

Overall, the safety of natural gas systems is a priority. With one of the above overpressure protection methods, you can guarantee safety even if your pressure regulator malfunctions or fails. The relief valve releases excess pressure to the surroundings, while the slam-shut valve closes a flapper to prevent more gas flow when it exceeds a specified point. A relief monitor quickly brings a monitor into operation by venting excess gas to reduce pressure, whereas in series regulation and a worker/monitor, OPP is achieved by containment of excess gas.

Norgas distributes gas regulators, relief valves, gas valves, and meters across Canada. We have a large inventory of products and parts in stock and ready to ship. Please feel free to contact our technical experts, they can help you select the right product for your application.